SCOTT HARLAN P.E.

Mechanical Engineering

Consultant

Scott Harlan P.E.

California Professional Engineer License M31719

scott@scottharlanpe.com

(831)-210-4645

19518 Creekside Ct.

Salinas, California 93908

Mobile Hydraulics System Design

- Hydraulic System Design

- Cost Reduction

- Hydraulic Leak Reduction

Mobile hydraulic systems pose a unique set of design challenges. The hydraulic tanks tend to be small, and often times the packaging problems are significant. My experience designing hydraulic systems for mobile equipment has ranged from systems with a few simple functions to complex designs with proportional control and feedback. Depending on your production volume I can help you design systems using discreet hydraulic valves or custom hydraulic manifolds to suit your specific need.

Hydraulic system reliability is a result of many factors. These factors include system dynamics, fitting selection, component selection, operating temperature and fluid selection. If you have a hydraulic system that is chronically leaking or suffering other reliability issues, my review of your system may help resolve these problems.

Hydraulic components often represent a significant part of the equipment cost when building a piece of mobile equipment. Hydraulic salesmen often design hydraulic systems using whatever component manufacturers they represent instead of the most cost effective or appropriate part for the project. I can review your hydraulic system and make suggestions to reduce your system cost or improve the performance.

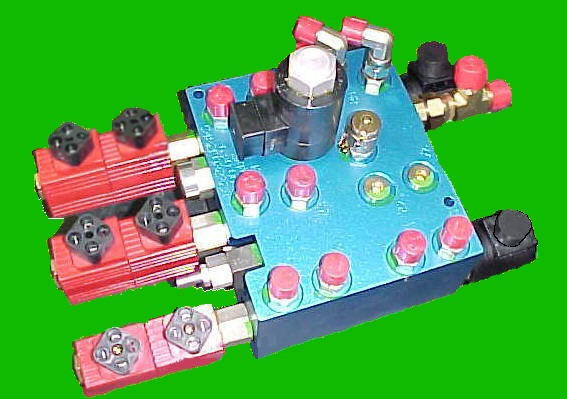

Hydraulic manifold was designed to operate seven mechanisms while fitting in a narrow 10" envelope.

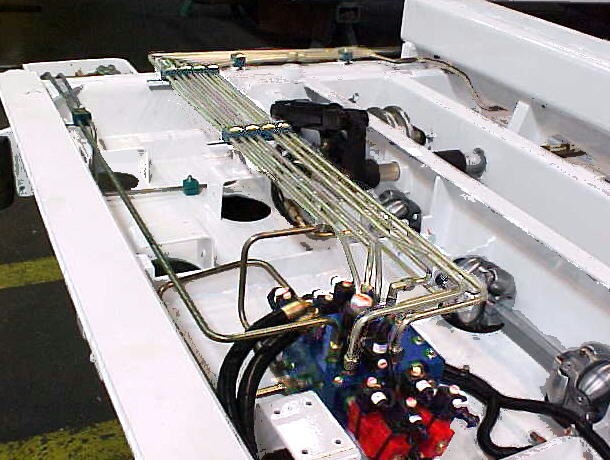

Attention to serviceability was critical in the design of this cargo loader hydraulic system.

The hydraulic system on this spinach harvester uses a single pressure compensated pump to operate all of the functions. The ground drive is under direct hydraulic control to maximize system reliability.