SCOTT HARLAN P.E.

Mechanical Engineering

Consultant

Scott Harlan P.E.

California Professional Engineer License M31719

scott@scottharlanpe.com

(831)-210-4645

19518 Creekside Ct.

Salinas, California 93908

Scott Harlan P.E.

19518 Creekside Ct.

Salinas, CA. 93908

Phone: (831)-210-4645

EDUCATION:

1982-1987 Bachelor of Science, Mechanical Engineering; University of Colorado.

1982-1987 Bachelor of Arts, Political Science, University of Colorado.

1991 Completed Beginning Algor Finite Element Analysis Training

2008 Completed Beginning and Intermediate Solidworks Modeling and Drawing Training

PROFESSIONAL MEMBERSHIPS and PATENTS:

California Registered Professional Engineer #M31719.

Inventor on U.S. Patents:

5,525,019- Rear platform lift mechanism for aircraft cargo loader.

5,713,600- Fail safe stabilizer leg for aircraft cargo loader.

5,211,413- Trailer with movable undercarriage.

Application 20130084151- Portable transfer Dock.

EXPERIENCE:

2014-Present: CEO of CAULDRON LLC, Salinas, California.

- Machinery and machinery parts company with a focus on engineering and manufacturing the world's best mechanical parts.

2012-Present:

Engineering Consultant, Salinas,

California.

Consulting work has included several diverse projects.

- Improving

the reliability of a tomato harvesting machine prototype from 17%

up time to 70% up time in a period of three

months.

- Refining

the hydraulic system design on a marine research

vessel.

- Developing a conceptual model and prototype of a machine to assist in harvesting strawberries. Convert this prototype to solar power.

- Design of experimental mechanism for trimming lettuce.

2006-2012: Director of R&D Ramsay Highlander, Inc.

- Spinach Harvester track drive so cost effective it is about 20% less expensive to manufacture than wheel drive.

- Time saving hands free automatic leaf strippers to remove leafs from greenleaf lettuce stems.

- Nimble Celery Machine with novel dual track drive that reduces to 102" wide for transport.

- Audacious tomato machine that is the first in the industry to harvest, separate and offload both red and green tomatoes simultaneously (one of several designers). Once fully implemented will eliminate 80% of labor requirement.

- Versatile self propelled loading dock that runs on engine power or battery power and can be towed at highway speeds.

- Revolutionary Romaine harvester cuts lettuce using ultra high pressure water. The first commercially successful mechanical lettuce harvester. Slashes the manpower requirement in half.

In 2000 earned my Professional Engineering license. Consulting work included a diverse range of design projects:

- Designed tooling to move machine enclosures for Haas Automation.

- Pioneered design of hydraulic and mechanical alternative energy system for AEST.

- Cut cost and weight of military truck components for Stewart and Stevenson.

- Developed hydraulic system for hybrid drive test stand for BAE.

- Feasibility study and conceptual model of track drive test fixture for BAE.

- Solved fatigue and reliability problems on more than 100 components for Indian Motorcycle.

- Managed Current Product group for Indian Motorcycle.

- Spinach harvester with low cost but full functionality for Ramsay Highlander Inc.

1998-2000: Engineering Manager, TLD Lantis, Salinas, California.

- Supervised design and construction of large hydraulic fixtures for key weldments.

- Coordinated engineering efforts between American factory and French sister company.

- Extensive cost and weight reduction through material and process changes.

- Developed the U.S. version of high capacity cargo loader which eventually became the corporate standard.

- Traveled internationally to visit customers and sister companies.

- Developed unique and cost effective proportional hydraulic system for new family of aircraft cargo loaders.

- Designed and performed finite element analysis on cargo loader scissor lifts and chassis.

- Created ultra rugged chassis for cargo loader

- Designed modular system of compatible options for different machine widths, lift heights

- Reduced cargo loader weight (15%) and cost(25%) through use of HSLA steels and other improvements.

- Designed custom hydraulic tilt trailers.

- Developed tow mechanism, stabilizers, and winches for two military wrecker bodies. Successful wrecker design helped Stewart and Stevenson procure a truck contract in excess of one billion dollars.

- Principal engineer on second iteration of military wrecker body.

- Prototyped folding trailer for hauling combines.

- Developed Geometric Tolerance coarse and taught to shop and engineering personnel.

- Managed downtown engineering office for last two years.

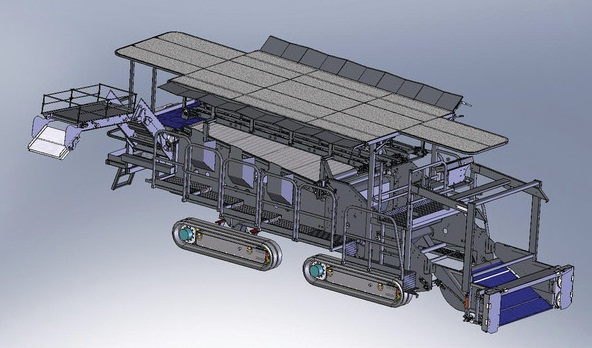

This Greenleaf lettuce harvester was modeled in its entirety in Solidworks